TURBOFLO Fluids are designed to significantly exceed the demanding service requirements of steam and gas turbine operators. They also provide extended, corrosion-free lubrication of bearings operating at temperatures above 260°C or 500°F.

Product Description

Introduction

Petro-Canada’s TURBOFLO Fluids are specifically designed to lubricate and cool steam and gas turbines and deliver excellent lubrication to bearings. They are exclusive blends of ultra pure Petro-Canada HT Severely Hydrocracked base oils and a unique Petro-Canada additive system. TURBOFLO Fluids demonstrate exceptional oxidative and thermal stability.

Features and Benefits

1. Exceptional resistance to fluid breakdown caused by air and high temperatures

For example:

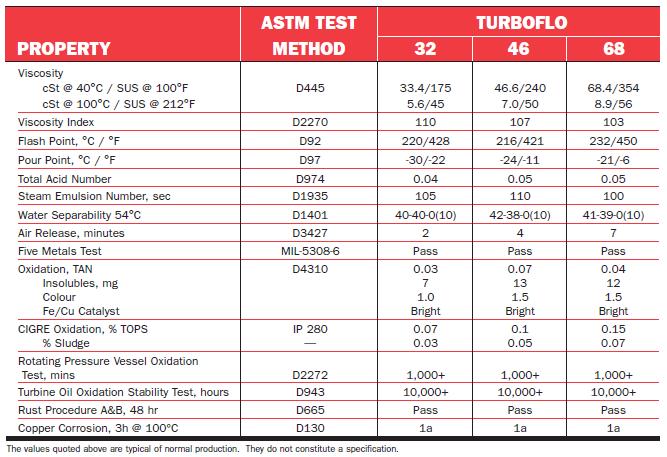

Turbine Oxidation Stability Test result exceeds 10,000 hours – much higher than the industry standard. Rotating Pressure Vessel Oxidation Test (RPVOT) result exceeds 1,000 minutes

• Significantly extends oil life particularly after a complete fluid change-out.

• Topping-up an existing turbine oil system, provides an immediate and marked improvement in oil performance

• Lowers operating costs by extending intervals between oil top-ups or complete change-outs

2. Excellent water separability

• Drainage of condensed water from oil coalescers and purifiers is greatly facilitated

• Condensed water meets environmental guidelines

3. Extremely rapid air and gas separation

• Less fluid break down

• Improves equipment reliability

Applications

TURBOFLO Fluids are designed to significantly exceed the demanding service requirements of steam and gas turbine operators. They also provide extended, corrosion-free lubrication of bearings operating at temperatures above 260°C or 500°F.

1. Steam Turbines

TURBOFLO Fluids are recommended for lubricating steam turbines used for electric power generation and other industrial applications. TURBOFLO Fluids deliver excellent performance over the entire life of the fluid. In large power generation plants, turbine oil is used for several years until degradation of the oil causes poor water separability and low oxidation resistance (low RPVOT values). Because of TURBOFLO’s high oxidation resistance (high RPVOT values) and fast water separability, even a partial oil replacement with TURBOFLO can return an entire oil system to acceptable standards. TURBOFLO 32 is recommended for use in large turbines (100 -1300 megawatts) coupled directly to an electric generator. TURBOFLO 32 and 46 are approved by Ontario Hydro against their M-332M specification.

TURBOFLO 46 and 68 are recommended for use in smaller steam turbines (up to 50 mega-watts), which drive an electric generator through a reduction gear-drive. TURBOFLO Fluids are suitable for use in steam turbines requiring the following manufacturer specifications:

General Electric GEK 28143A, GEK 46506D

Siemens TLV 9013 04 (non-EP)

ABB K 110 812101

2. Gas Turbines

TURBOFLO Fluids are recommended for the lubrication of the high-speed bearings in stationary gas turbines. Major utility, pipeline and gas field recovery and cogeneration operators have recognized the performance of TURBOFLO compared to conventional mineral oil turbine fluids. TURBOFLO Fluids are suitable for use in gas turbines requiring the following manufacturer and industry specifications:

General Electric GEK 32568F

Westinghouse 1500 00 20

Solar ES 9224

Cooper SE 1144

Siemens TLV 9013 04 (non EP)

ALSTOM (ABB) HTGD 90117

ASTM D4304 Type I (non-EP)

3. High Temperature Bearings

TURBOFLO Fluids exceed General Electric specifications for bearings operating at temperatures above 260°C or 500°F. This demonstrates the fluids are ideal for use in high temperature applications, requiring a lubricant with high thermal and oxidative stability.

Typical Performance Data

| See also different: | |